3D modeling significantly reduces the number of interferences and errors that can occur in highly congested areas.

Time and money spent by your selected contractor to generate such documents early in the construction phase can be eliminated, improving your project schedules and saving you money. Piping fabrication isometrics and bills of material are easily extracted from the 3D computer model, resulting in better quality mechanical contractor bids delivered in less time.The benefits of using 3D modeling can be realized in all phases of a project:

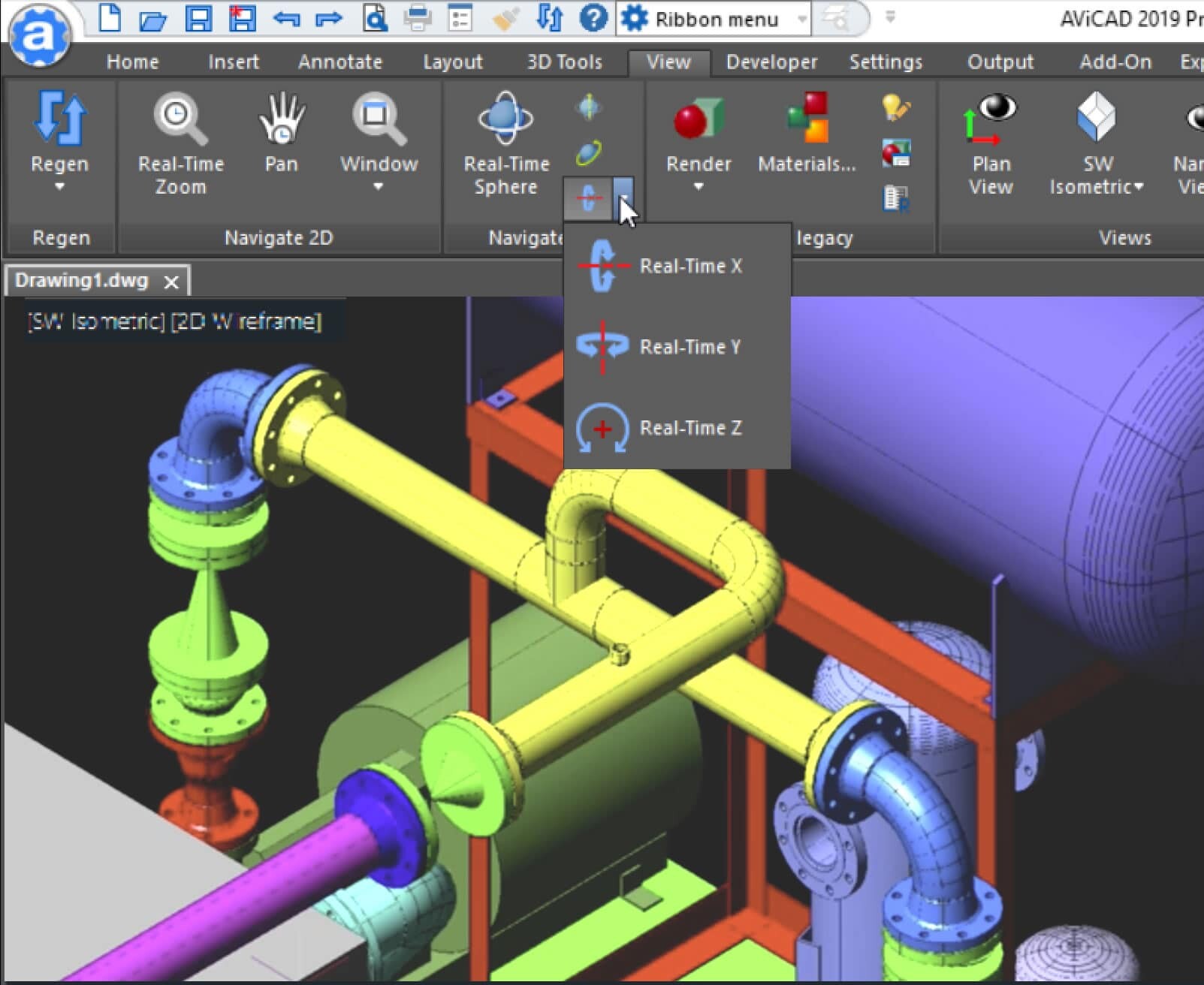

Our design specialists use several different kinds of software packages tailored to your project needs, including:ģD modeling software from Intergraph (PDS®, CADWorx®, SmartPlant®), Bentley (AutoPIPE®, AutoPLANT®, Navigator®, OpenPlant®), Autodesk (Revit®), and CEA Systems (Plant-4D)Ĭaesar® II by Intergraph (used for stress analysis) Using specialized software and 3D modeling, we are able to take you on a virtual tour of design layout options, providing your engineering, production, and maintenance staff with a greater understanding of how new or renovated facilities will look and operate after construction.

Our focus is on safety, efficiency, and accessibility. IPEC brings a multidiscipline approach to the design and layout of process piping, utility piping, and bulk material handling systems. We optimize your process designs for efficient construction, installation, validation, start-up, training, operation, and maintenance to reduce your costs and shorten project delivery schedules. Our process design specialists conduct detailed assessments to understand and implement designs that integrate cost effective, efficient, and appropriate process technology for your manufacturing and business needs. Our capabilities include the fabrication and installation shop drawings of process and all necessary process detail engineering needs for our customers. IPEC specializes in turnkey field industrial pipe and steel process system design.

0 kommentar(er)

0 kommentar(er)